Type: Steam

Capacity: 15 Ton

Industry: Paper Industry

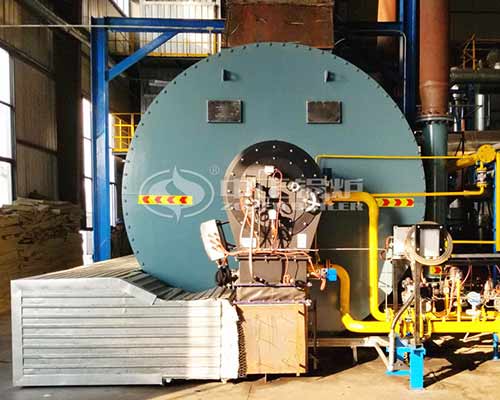

Equipment: WNS15-1.25-Q

Customer Feedback

When choosing boiler equipment, we pay the most attention to environmental protection standards. The low-nitriding combustion technology of ZOZEN Boiler makes the nitrogen oxide emission far lower than the industry standard, which provides strong support for our environmental certification. This boiler not only meets production needs, but also helps us fulfill our commitment to green and sustainable development.