Introduction

Steam generation in boilers is a fundamental process in various industries, where thermal energy is converted into steam through combustion, heat transfer, water heating, steam separation, and distribution. This article explores the basic principles and steps involved in steam generation in boilers, discusses innovative technologies currently applied in the steam boiler industry, introduces a range of efficient steam generation in boiler products offered by ZOZEN, and highlights ZOZEN’s commitment to technological advancements.

Part 1: Basic Principles and Steps of Steam Generation in Boiler

Steam generation in boilers involves several key processes that work together to produce steam efficiently. These processes include:

Fuel Combustion: The primary step is the controlled combustion of fuel, such as oil, gas, coal, or biomass, in the boiler’s combustion chamber. The heat generated from the burning fuel provides energy for steam generation.

Heat Transfer: The heat produced from fuel combustion is transferred to the water-filled tubes or walls of the boiler. This heat transfer raises the temperature of the water and converts it into steam.

Water Heating: The water within the boiler absorbs the heat from the combustion process, increasing its temperature. As the water reaches its boiling point, it undergoes a phase change and transforms into steam.

Steam Separation: Once steam is generated, it needs to be separated from the remaining water. This separation is typically achieved through specialized equipment, such as steam drums or separators, which remove any moisture or impurities from the steam.

Steam Distribution: After separation, the steam is distributed to various parts of the industrial process or used for power generation. Proper steam distribution ensures efficient utilization of the generated steam.

Part 2: Innovative Technologies in Steam Generation

The steam boiler industry continually embraces innovative technologies to enhance steam generation in boiler efficiency, energy utilization, and environmental protection. Some notable advancements include:

High-Efficiency Combustion Systems: Advanced combustion systems improve fuel efficiency, reduce emissions, and optimize the combustion process for different fuel types.

Heat Recovery Systems: These systems capture waste heat from flue gases or exhaust streams and utilize it to preheat incoming feed water, resulting in higher overall system efficiency.

Intelligent Control Systems: Integrated control systems with advanced algorithms enable precise monitoring and control of various parameters, optimizing boiler performance and reducing energy waste.

Part 3: ZOZEN’s High-Efficiency Steam Generation Products

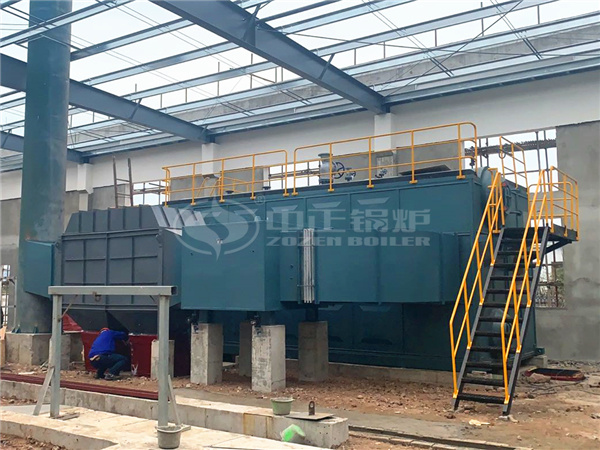

ZOZEN offers a range of steam generation products designed to maximize efficiency and meet diverse industry needs. The following are some of ZOZEN’s renowned products:

WNS Series: This oil and gas-fired boiler series offers a thermal capacity of 1-20 t/h and a working pressure range of 0.7-2 MPa. Its compact design and efficient performance make it suitable for various industrial applications.

SZS Series: The SZS series features a D-type layout, providing a thermal capacity of 2-110 t/h and working pressure range of 1.25-5.3 MPa. It excels in large-scale applications where high steam demand is required.

DZL Series: The DZL series includes single-drum coal and biomass-fired boilers. It offers a thermal capacity of 2-10 t/h and a working pressure range of 1-2.5 MPa. The DZL series also includes a tri-drum biomass-fired boiler with a thermal capacity of 15-40 t/h and a working pressure range of 1.25-2.5 MPa.

SZL Series: Designed as a dual-drum coal and biomass-fired steam boiler, the SZL series provides a thermal capacity of 6-35 t/h and a working pressure range of 1-2.5 MPa. Its robust construction and high efficiency make it suitable for industrial processes requiring large amounts of steam.

Each product from ZOZEN offers specific advantages, including reliable performance, compact design, high thermal efficiency, and advanced control systems, ensuring optimal steam generation in boilers.

Part 4: ZOZEN’s Commitment to Technological Advancements

ZOZEN is dedicated to continuous research and development, focusing on enhancing steam generation efficiency and implementing intelligent control systems. Their investments in cutting-edge technologies and engineering expertise have resulted in significant achievements. ZOZEN’s innovations include improved combustion systems, advanced heat recovery solutions, and intelligent control interfaces, all aimed at optimizing steam generation processes and improving overall boiler performance.

Conclusion

Steam generation in boiler is a complex process involving fuel combustion, heat transfer, water heating, steam separation, and distribution. The steam boiler industry continues to evolve with innovative technologies that enhance efficiency, energy utilization, and environmental sustainability. ZOZEN’s comprehensive range of steam generation products, backed by their commitment to technological advancements, offers efficient steam generation solutions for various industrial applications. With their high-performance boilers and continuous focus on research and development, ZOZEN remains at the forefront of the steam boiler industry, providing reliable and sustainable solutions for steam generation in boilers.