Acting as an important piece of heat source equipment on the production line of textile enterprises, the steam boiler system will directly affect the quality of textiles and the economic benefits of the enterprise. Due to its excellent quality boilers, ZOZEN has provided the reliable heat source guarantee for overseas production bases of many textile enterprises.

Based on the local conditions of Vietnam and the company’s actual needs, ZOZEN customized SZL series coal-fired steam boiler systems for the Textile (Vietnam) Co., Ltd. This series of boilers is environmentally friendly and efficient, and has a strong overload capacity and a wide adaptability of fuels.

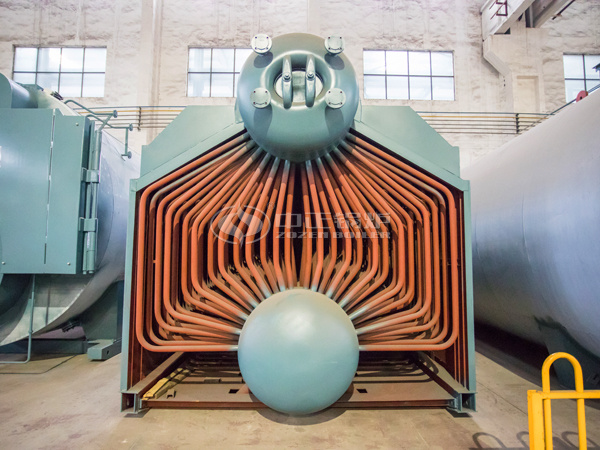

At the same time, the boiler furnace is composed of water-cooled wall tubes, front and rear arches and grate. The dense convection tubes are arranged at the rear of the boiler body, which fully meet the heat source required by the customer. The entire steam boiler system not only has high thermal efficiency, but the supporting dust removal equipment also meets local environmental protection emission requirements.

Since exploiting overseas markets in 2011, ZOZEN’s boilers have been highly favored by the Southeast Asian market, and have continued to expand their sales territory. They have been well exported to more and more countries such as Australia, the United Arab Emirates, Mexico, Kenya, and Chile. ZOZEN not only actively deploys overseas markets, but also works with more and more Chinese enterprises to expand overseas sales. General Science set up plants in Thailand, Deli Group set up plants in Vietnam, ect., all of them have chosen ZOZEN as a reliable and stable boiler supplier.

With over 30 years’ development, ZOZEN has successfully developed a number of patented boiler technologies, leading the development direction of the industrial boiler industry. For the manufacture of chain grate boilers, ZOZEN not only adopts multiple independent wind chambers and air conditioning doors, but also uses multiple draft fans to supply air, which have independent air conditioning functions. Users can adjust the air flow from the front to the back according to the different types of coal and load during the operation, ensuring that the boiler combustion is always in a good state.