Nowadays, science and technology are developing rapidly. With the purpose of reducing costs by using convenient and efficient boilers, clients set higher requirements for the convenience of industrial boilers. ZOZEN launched gas-fired (oil-fired) skid mounted steam boiler for the requirements of overseas market, which has solved the installation problems of client’s concern.

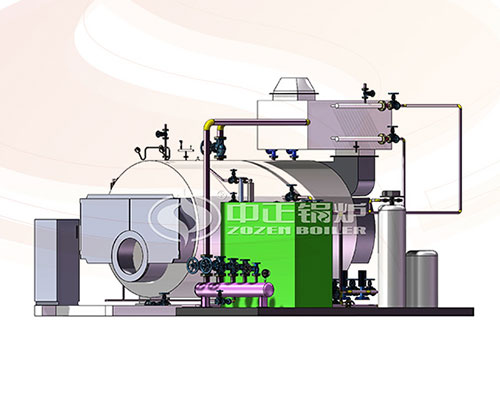

The skid mounted steam boiler is to install all the equipment such as the boiler proper, economizers, burners, valve instruments, electric control cabinet, water treatment, economizer circulating pumps, feeding pumps, deaerators on one or two skids to form an integral movable boiler system. All the pipes and valves on the skid have been installed, furthermore, the connecting pipes between the skids have also been installed in the factory, which can save plenty of costs for clients. This kind of boilers is especially suitable for the food industry, the chemical industry, the textile industry, the medicine industry, the rubber industry, the building materials industry and so on.

ZOZEN gas-fired steam boiler got the favor of Kenya oil giant KPC and Xindaxin Food Burma Factory with excellent advantages of skid mounted package delivery and short installation period. The sales manager of ZOZEN learned about that the existing coal-fired steam boiler of Xindaxin with settings of dust collectors, gas flues, induced draft fans, coal pile and slag field covered a large area. The total area of the gas-fired (oil-fired) skid mounted steam boiler is only 1/10 of the coal-fired boiler with the same capacity. In consideration of the factory situation and environmental protection, Xindaxin decided to introduce the gas-fired (oil-fired) skid mounted boiler with characteristics of compact structure and clean operation environment.

ZOZEN customized a full set of skid mounted steam boiler system for Xindaxin according to its actual demands. The manager of Xindaxin had a better understanding about ZOZEN’s quality control and service assurance after conducting a field inspection at ZOZEN’s modern intelligent factory.

Although the installation procedure of the skid mounted steam boiler can be omitted, the commissioning work cannot be ignored. Out of the trust of ZOZEN, the manager of Xindaxin chose the scheme that the ZOZEN technicians finished commissioning at factory before delivery. The gas fired steam boiler could be put into operation by just connecting gas, electricity and oil as soon as it was delivered to the construction field. Compared with field commissioning, this solution can save lots of costs for clients.

In the aspect of security, this series of boilers is equipped with telecommunication function, users can monitor the operation condition of boilers by mobile phones and computers. In the aspect of service, ZOZEN will provide regular online return visit service and answer questions remotely, solving boiler problems for users at any moment, from anywhere.With the coming of 2022, ZOZEN will speed up the expansion of overseas market with the strength of technology and service, striving to become a global brand.